Overview:

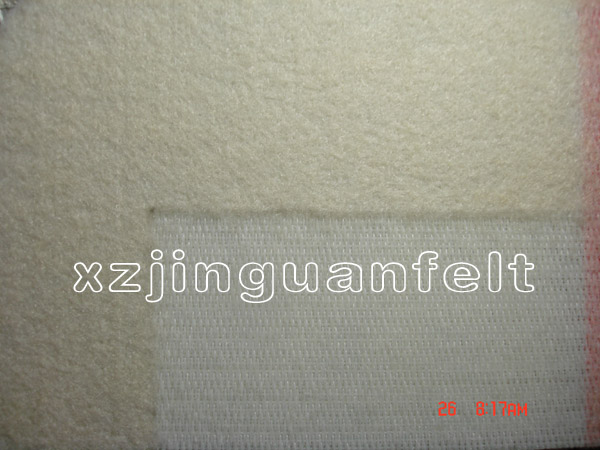

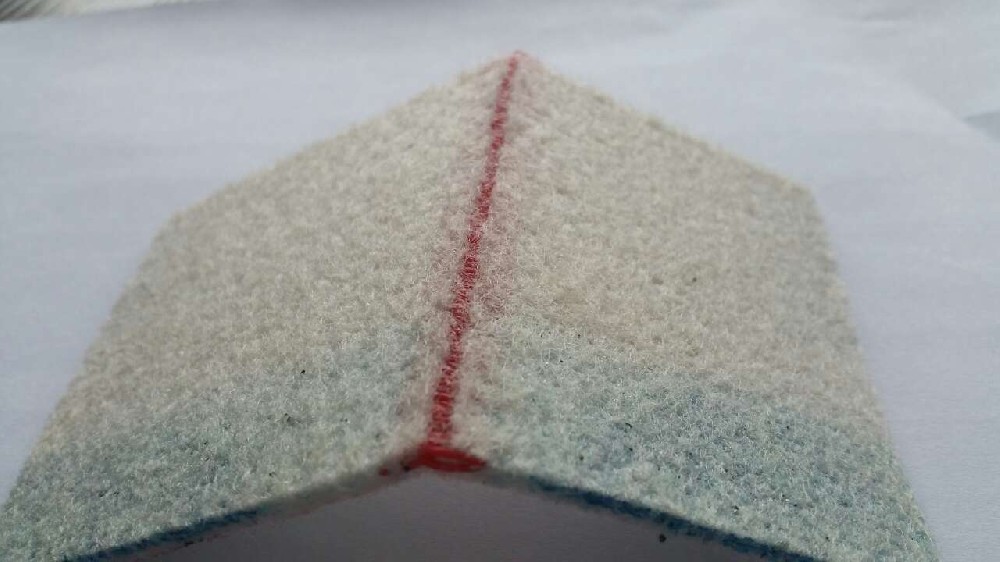

The endless flocking dry net adopts the endless seam polyester woven dry net as the base net, and then implants a certain fineness and quantity of high temperature resistant short fibers on the front and back of the dry net at the same time. The seam adopts spiral ring pin connection; adopts international The high-quality German Groz Beckert Group and the American Foster Needle Company produce needles; use reasonable routing distance, needle speed, needle depth, needle (empty) needle penetration times and other processes; select high temperature resistant and anti-aging Synthetic fiber mixing ratio; adopt reasonable amount of wool spreading, setting of layer of wool spreading and fineness of wool mesh fiber; use the most advanced double-sided three-needle needle punching machine and hot oil roller setting machine in China. The produced flocking dry net has a smooth and delicate mesh surface, a reasonable structure ratio, tighter and stronger bonding between fibers, less hair removal and hair loss, high tensile strength, stable size, no mesh marks on the paper surface, and air permeability. Large, not easy to shed hair, wear resistance, anti-aging, long service life and other characteristics. It is widely used for papermaking in the dryer section of medium and high-speed papermaking machines, which requires extremely high drying rate and wire marks, and is especially suitable for papermaking of high-end, medium-low weight special paper.

中文版

中文版 English

English