Performance introduction of special papermaking felt for high-speed tissue paper

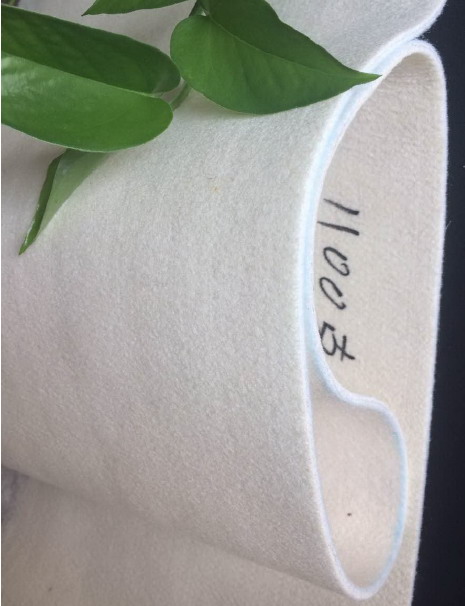

The high-speed tissue paper special blanket is made of advanced bottom net weaving technology and multi-axial bottom net structure. It is laid out by mixing raw materials of different ingredients with the best performance in the world. The concepts of dehydration, vacuum mesh cage dehydration and vacuum roller dehydration. The 10.0m wide carding machine used by Haigh Chadwick in the United Kingdom was used to comb and lay the wool net. The 15.0M wide heavy loom imported from Sweden TEXO and the Master SM 92 high-speed loom imported from Italy Somet were used to weave the bottom net. The 8.5-meter wide four-needle area heavy-duty needle punching machine is used for needle punching and laying the fleece. The 9.0-meter wide hot oil roller setting machine is used to add pressure, washing, vacuum suction, chemical treatment, singeing and other devices to shape the felt and sort out.

The product has the following advantages: good initial adaptability, fast speed increase, stable operation, soft paper production without any holes, can effectively save steam consumption and power consumption, stable performance during use, etc. The service life is basically equivalent to imported paper blankets , Is a very cost-effective paper blanket.

This product can meet the needs of producing high-end household paper such as crescent-shaped paper machines above 1100m / min and BF series paper machines above 800m / min.

中文版

中文版 English

English